Type of Compressor Used in Ships

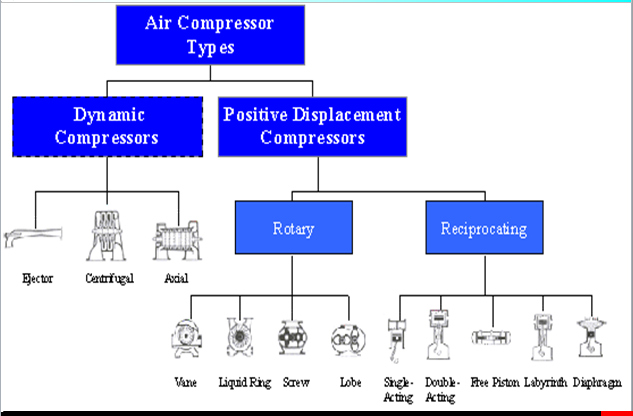

Compressors can be classified according to the principle of compression:

- Dynamic compressor

- Positive displacement compressor

read the: Function Air Compressor On a Ship

1.Dynamic compressor

Increasing the pressure of gases by imparting to it the kinetic energy, which is converted into pressure energy by a diffuser.Air is forced into space and energy is added to it by increasing the velocity. Velocity will decrease by volute casing or diffuser. Thus loss of velocity will cause the pressure to increase at the discharge side of the compressor.

This type of compressor where the gas moved into the compressor is acted upon, moved through the compressor and discharged without interruption of the flow at any point in the process (under continuous mode)

These are multi-blade compressors and are further subdivided into:

- A.Centrifugal compressor

- B.Jet compressor

- C.Axial Flow

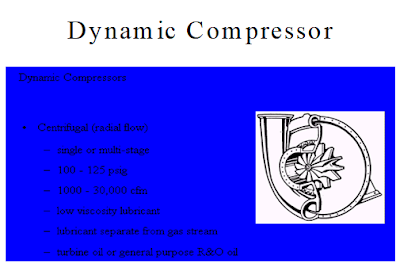

A.Centrifugal Air Compressor

A high peripheral velocity is imparted to the gases being compressed by the blades of the impeller which rotate at a speed of 3000 to 27000 rpm to produce high-pressure discharge or by converting angular momentum imparted by the rotating impeller (dynamic displacement)

The centrifugal force developed in this way partially compress the gases. Further compression occurs in diffuser by reducing its velocity which is depending upon the direction of gases flow at outlet from impeller compressor which can be radial or axial compressor

The centrifugal force developed in this way partially compress the gases. Further compression occurs in diffuser by reducing its velocity which is depending upon the direction of gases flow at outlet from impeller compressor which can be radial or axial compressor

The centrifugal force utilized by the centrifugal compressor is the same force utilized by the centrifugal pump. The air particles enter the eye of the impeller then is thrown against the casing

The air becomes compressed as more and more air is thrown out to the casing by the impeller blades

The air is pushed along the volute casing cause pressure of the air to increase

The impeller blades curve forward, which is opposite to the backward curve used in typical centrifugal liquid pumps or can use a variety of blade orientation including both forward and backward curves.

There may be several stages to a centrifugal air compressor, as in the centrifugal pump, and the result would be the same; a higher pressure would be produced.

The air compressor is used to create compressed or high pressure air for a variety of uses. Some of its uses are pneumatic control devices, pneumatic sensors, pneumatic valve operators, pneumatic motors, and starting air for diesel engines.

However, centrifugal compressors are now most frequently used for medium volume and medium pressure air delivery. One advantage of a centrifugal pump is the smooth discharge of the compressed air. Diesel Engine Turbochargers

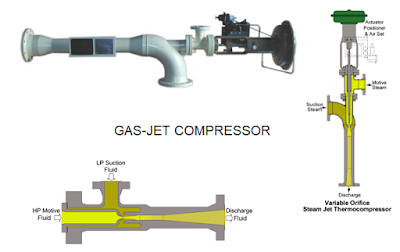

B.Jet Compressor

In jet compressor it’s driving vapour attains a high supersonic velocity in a Laval nozzle and then mixed with the gases to be compressed in a mixing chamber and leading it at high velocity to the diffuser where kinetic energy is converted into pressure energy

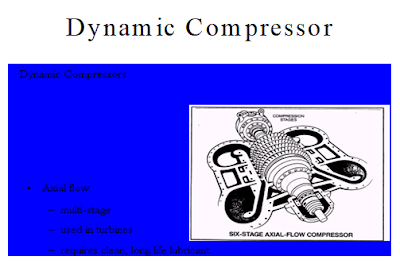

C.Axila Flow

2.Positive displacement compressor

It operates by volumetric displacement by means of increasing the pressure of gasses by decreasing its volume. It can be achieving by first, traps a volume of air in the cylinder then displace it into small spaces.

This type of compressor considered under intermittent mode of compressor where is cyclic in nature, in that a specific quantity of gas is ingested by the compressor, acted upon, and discharged, before the cycle is repeated

It can be subdivided into;

- A.Rotary compressor The gas volume changes due to rotation in the cylinder of rotary vanes of an eccentrically place rotor.

- B.Reciprocating or piston compressor The gas volume changes due to the action of one or two reciprocating pistons moving axially in cylinder.

A.Rotary Compressor

Rotary air compressors are positive displacement compressors. The most common rotary air compressor is the single stage helical or spiral lobe oil flooded screw air compressor. These compressors consist of two rotors within a casing where the rotors compress the air internally. There are no valves.

These units are basically oil cooled (with air cooled or water cooled oil coolers) where the oil seals the internal clearances. Used for Low/Medium pressure (e.g., Deck air, grit blasting, painting)

Rotary compressor units are classified into three general groups

- Slide vane-type,

- Lobe-type and helical type

- Liquid seal ring-type.

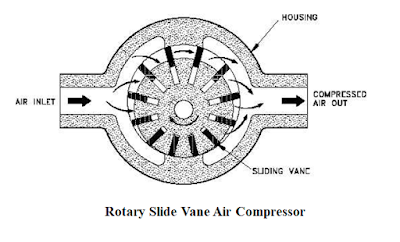

Slide vane type

The centrifugal force carries the sliding vanes against the cylindrical case with the vanes forming a number of individual longitudinal cells in the eccentric annulus between the case and rotor.

The suction port is located where the longitudinal cells are largest. The size of each cell is reduced by the eccentricity of the rotor as the vanes approach the discharge port, thus compressing the air.

Rotary lobe type

The suction to the unit is located where the cavity made by the lobes is largest. As the lobes rotate, the cavity size is reduced, causing compression of the vapor within.

The compression continues until the discharge port is reached, at which point the vapor exits the compressor at a higher pressure.

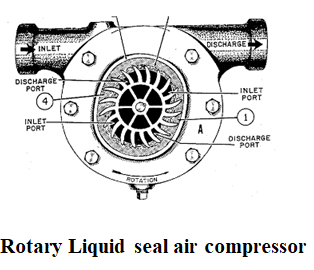

Liquid seal ring-type

Features a forward inclined, open impeller, in an oblong cavity filled with liquid. As the impeller rotates, the centrifugal force causes the seal liquid to collect at the outer edge of the oblong cavity.

Due to the oblong configuration of the compressor case, large longitudinal cells are created and reduced to smaller ones.

The suction port is positioned where the longitudinal cells are the largest, and for the discharge port, where they are smallest, thus causing the vapor within the cell to compress as the rotor rotates.

The rotary liquid seal compressor is frequently used in specialized applications for the compression of extremely corrosive and exothermic gases. (commonly used in commercial nuclear plants as a means of establishing initial condenser vacuum) Stripper System priming devices on tankers

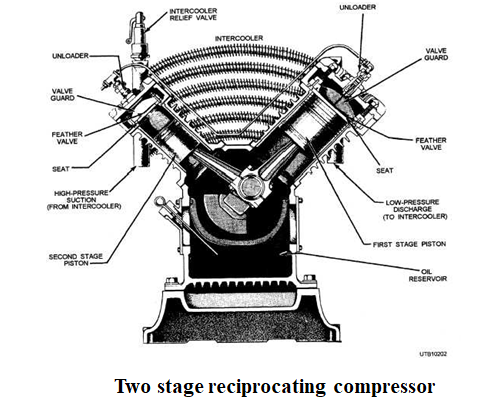

B.Reciprocating or piston compressor

Reciprocating air compressors are positive displacement compressors. This means they are taking in successive volumes of air which is confined within a closed space and elevating this air to a higher pressure. The reciprocating air compressor accomplishes this by using a piston within a cylinder as the compressing and displacing element

It was the most common design employed today

The reciprocating air compressor is considered single acting when the compressing is accomplished using only one side of the piston. A compressor using both sides of the piston is considered double acting.

The reciprocating air compressor uses a number of automatic spring loaded valves in each cylinder that open only when the proper differential pressure exists across the valve.

1 komentar:

komentarThe post is written in very a good manner and it entails many useful information for me. I am happy to find your distinguished way of writing the post. Now you make it easy for me to understand and implement the concept. Repair Air Compressor

Replysilahkan berkomentar secara bijak dan sesuai dengan topik pembahasan. TERIMAKASI