How Are Ship Engines Cooled

Although there is an abundance of free sea water available, marine diesel engines do not use it directly to keep the hottest parts of the engine cool. This is because of the corrosion which would be caused in the cooling water spaces, and the salts which would be deposited on the cooling surfaces interfering with the heat flow.

Instead, the water circulated around the engine is fresh water ( or better still, distilled water) which is then itself cooled using sea water. This fresh water is treated with chemicals to keep it slightly alkaline ( to prevent corrosion) and to prevent scale formation. Of course, if distilled water, which some ships can make from sea water using evaporators, is used then there is a reduced risk of scale formation.

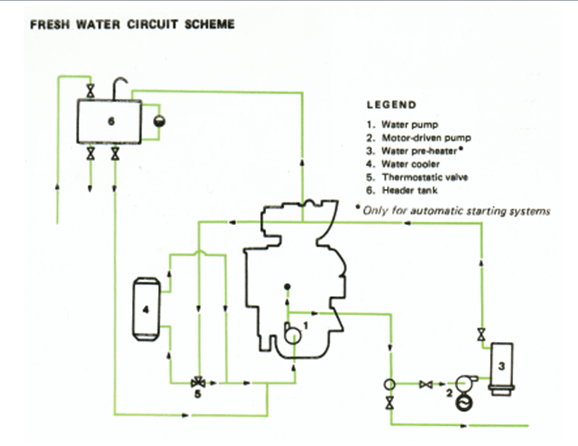

The cooling water pump which may be engine driven or be a separate electrically driven pump pushes the water around the circuit. After passing through the engine, where it removes the heat from the cylinder liners, cylinder heads, exhaust valves and sometimes the turbochargers, it is cooled by seawater and then returns to the engine. The temperature of the cooling water is closely controlled using a three way control valve to by pass the cooler.

If the water is allowed to get too cold then it will cause thermal shocking which may lead to component failure and will also allow water and acids to condense on the cylinder bores washing away the lubricating film and causing corrosion. If it gets too hot then it will not remove the heat effectively causing excessive wear and there is a greater danger of scale formation. For this reason the cooling water outlet temperature is usually maintained at about 78°C.

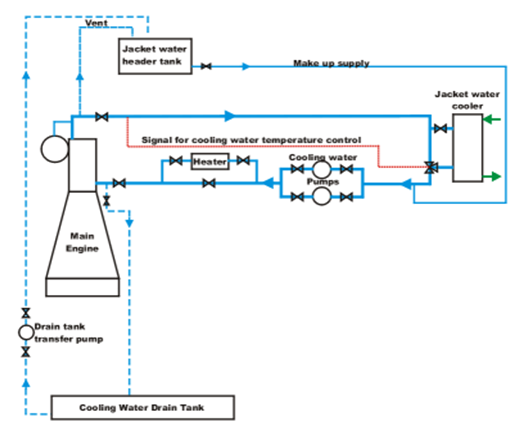

To make up for any leaks in the system there is a header tank, which automatically makes up any deficiency. Vents from the system are also led to this header tank to allow for any expansion in the system and to get rid of any air (if you are familiar with a domestic central heating system then you will see the similarities). The header tank is relatively small, and usually placed high in the engine room.

It is deliberately made to be manually replenished, and is fitted with a low level alarm. This is so that any major leak would be noticed immediately. Under normal conditions, the tank is checked once per watch, and if it needs topping up, then the amount logged.

The system will also contain a heater which is to keep the cooling water hot when the engine is stopped, or to allow the temperature to be raised to a suitable level prior to starting. Some ships use a central cooling system, whereby the same cooling water is circulated through the main engine(s) and the alternator engines. This system has the advantage whereby the engines which are stopped are kept warm ready for immediate starting by the engines which are running.

Instead, the water circulated around the engine is fresh water ( or better still, distilled water) which is then itself cooled using sea water. This fresh water is treated with chemicals to keep it slightly alkaline ( to prevent corrosion) and to prevent scale formation. Of course, if distilled water, which some ships can make from sea water using evaporators, is used then there is a reduced risk of scale formation.

The cooling water pump which may be engine driven or be a separate electrically driven pump pushes the water around the circuit. After passing through the engine, where it removes the heat from the cylinder liners, cylinder heads, exhaust valves and sometimes the turbochargers, it is cooled by seawater and then returns to the engine. The temperature of the cooling water is closely controlled using a three way control valve to by pass the cooler.

If the water is allowed to get too cold then it will cause thermal shocking which may lead to component failure and will also allow water and acids to condense on the cylinder bores washing away the lubricating film and causing corrosion. If it gets too hot then it will not remove the heat effectively causing excessive wear and there is a greater danger of scale formation. For this reason the cooling water outlet temperature is usually maintained at about 78°C.

To make up for any leaks in the system there is a header tank, which automatically makes up any deficiency. Vents from the system are also led to this header tank to allow for any expansion in the system and to get rid of any air (if you are familiar with a domestic central heating system then you will see the similarities). The header tank is relatively small, and usually placed high in the engine room.

It is deliberately made to be manually replenished, and is fitted with a low level alarm. This is so that any major leak would be noticed immediately. Under normal conditions, the tank is checked once per watch, and if it needs topping up, then the amount logged.

The system will also contain a heater which is to keep the cooling water hot when the engine is stopped, or to allow the temperature to be raised to a suitable level prior to starting. Some ships use a central cooling system, whereby the same cooling water is circulated through the main engine(s) and the alternator engines. This system has the advantage whereby the engines which are stopped are kept warm ready for immediate starting by the engines which are running.

|

| typical cooling water circuit |

This system shows a typical cooling water circuit for a single medium speed engine with an engine driven main pump and an electrically driven auxiliary circ pump and heater for keeping the engine warm when stopped.

On this slow speed engine circuit a drain tank has been included. This is for when the engine is drained down for maintenance purposes. Because of the quantities of water involved and the chemical treatment, it is not economically viable or environmentally responsible to dump the treated water overboard each time. This way the water can be re used.

Quality requirement

- Engine cooling water is a consumable store which should be carefully selected and treated before the engine in operation and continually watched the specific concentration.

- If not, corrosion, erosion and cavitations may occur on the water sides of the cooling system and deposits may be formed.

- Deposits will impair heat transfer and may cause thermal overloading of the engine parts which have to be cooled.

- Corrosion and cavitations on the thrust side of the cylinder liners may occur in all water cooled combustion engines due to concerted action.

- Cylinder liner is set into vibrating motion with varying amplitudes and accelerations by the piston during working stroke resulting in negative and excess pressures at the interface of liner wall and cooling water.

- When the liquid is reaching vapour pressure, it forms vapour bubbles which as they collapse at the subsequent pressure rise in the course of positive stroke of the vibratory cycle of the liner wall, produce high local pressure and temperature peaks

- The impact intensity, which sets the liner into vibrating motion, depends on engine revolutions – less occurrence in medium and low speed engine

- Vibration Fissure* Corrosion is a damaging mechanism which is caused by dynamic and corrosive load simultaneously. This can be the cause for the formation of cracks and rapid progress of cracks in water-cooled mechanical loaded engine parts, due to faulty water treatment.

- Corrosion attack is avoided, when a cohesive (sticking) protective coating or surface film is form on the metal cooling surfaces by adding a corrosion inhibiting oil or a chemical corrosion inhibitor to the cooling water

- Laboratory tests and practical experiences confirm, that certain emulsifiable corrosion inhibitor oils are better in reducing successfully vibration fissure corrosion and cavitations than chemical inhibitors.

- Corrosion preventive oils forms oil-in-water emulsion, and the emulsifier in the oil provides for a protective layer on the metal cooling surfaces, which prevents corrosive damage.

Characteristic of cooling water

- Type of water →fresh water,free of impurities

- Total hardness →maximum 10o German hardness (*-1o German hardness – 10mg CaO in 1 L water)

- PH value at 20oC → 8

- Chlorine ion content →maximum 50mg/L

- Total hardness of water combines temporary and permanent hardness and mainly defined by the calcium and magnesium salts where →The hydrogen carbonate part of the calcium and magnesium salts determine the temporary hardness →The remaining calcium and magnesium salts (sulphates) determine the permanent hardness

- Water with a total German hardness of more than 10o should be diluted with distilled water or rain water or can be softened by chemical and vise-versa to protection against corrosion.

Effective application of corrosion

- A clean cooling system

- Suitable water

- Properly prepared cooling water for initial fill

- Continual supervision of the concentration

- The condition of the cooling system

Cooling water additives

- Anti-corrosion oil

- Chemical inhibitors

- Anti-freeze agents

Anti-corrosion oil

- This inhibitor is an emulsifiable mineral oil containing additional agents which will created a thin protective oil film and didn't affect heat transfer and prevent deposits on the metal surfaces of cooling water.

- Frothing (bubbling) can occur with oil emulsions, but this may be corrected by maintaining the PH between 8 and 9 by adding hardening powder such as calcium sulphate and 19% magnesium sulphate

- Anti-corrosion oils are not recommended and not suitable when there is a possibility of cooling water temperature dropping below 0oC or rising above 95oC

Chemical inhibitors

- Additions of sodium-nitride and sodium-nitride-borate basis have shown to be satisfactory.

- The regulation state that chromate in cooling water is prohibited if to be waste water disposal and fresh water generator system

- Nitride and nitrate are not suitable for galvanized pipes or in a cooling water system where cooling side is protected by zinc anodes

Note: corrosion inhibiting oils mixed with chemical additions may cause deposits in cooling water system and reduced heat transfer thus changing of those should entirely cleaned the system first.

Anti-freeze agents

- For example Clysantin 3059 is one of the suitable anti-freeze agents to be used when engine is operating at temperature below the freezing point of water.

- Its protect against corrosion and are also effective in protecting against cavitations.

- The additional water treatment is then not necessary cause an adequate corrosion protection is obtained when concentration is adjusted for low-temperature level

- Other anti-freeze medium agent may cause corrosion and therefore to be used for one winter

- Anti-freeze must not mixed each other otherwise (CI oil) emulsion will break and decompose at once and (C additive)different concentration of chemical additive may required

silahkan berkomentar secara bijak dan sesuai dengan topik pembahasan. TERIMAKASI